This week, I received a call from a manufacturing client who was struggling with a lack of customer satisfaction for one of their artist-quality acrylic paints. Apparently, the color on the bottles didn’t accurately reflect what the dried paint looked like by daylight, and the customers were demanding more precise labeling.

The problem, of course, is that this is an industry-wide issue.

In this case, I was able to help the client via a paradigm shift. By asking “what if?,” we came up with a solution that revolutionized their acrylic paint labels. I provided the client with the spectral analysis tools required to accomplish the task, and we journeyed into the artistic unknown.

Why Acrylic Paint Labeling Must Change

The problem with paint, of course, is that it dries. Most of the time, the dry shade differs (sometimes significantly) from the wet shade in the bottle, and differs yet again from the color swatch printed on the bottle label. Further complicating matters, the lighting under which the finished piece of art is displayed often renders the perceived color different yet again.

This presents a challenge when you are trying to advertise your product in color charts and catalogs (and, of course, in the bottle) and need to meet the high standards for artist-grade colors.

If labeling were to change, there is a largely open market to gain and the potential for a huge amount of brand loyalty. And if you’re a new manufacturer of acrylic paints and need to establish your reputation, a better label could set you apart. Spectrophotometry is the tool needed to break into this new market and enable a labeling revolution.

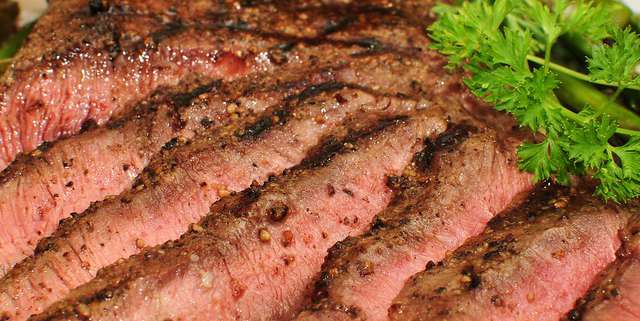

Color swatches on acrylic paints rarely display the dry paint shade with accuracy. Image credit: Flickr user Jim Winstead (CC BY 2.0)