Geformte Kunststoffteile

HunterLab verfügt über Instrumente und Probenhandhabungsgeräte, die nahezu alle Kundenanforderungen erfüllen. Ein solcher Bedarf, den wir erfüllen können, ist die Messung von geformten Kunststoffteilen, wie das oben abgebildete Teil. Diese Kunststoffteile sind eigentlich Abdeckungen für ein Bolzenfinderwerkzeug. Die Beschaffenheit dieser Teile bringt einige Schwierigkeiten bei der Farbmessung mit sich.

Eine der größten Herausforderungen besteht darin, dass die Teile gekrümmt sind, was die Messungen mit unserem Tischgerät erschwert. Diese Teile haben auch einen leichten Glanz und eine leichte Textur, die bei der Messung berücksichtigt werden müssen. Um die Glanzkomponente des Kunststoffteils zu berücksichtigen, muss es mit einem Kugelinstrument gemessen werden. Die Messung mit einem Kugelmessgerät stellt sicher, dass die Probe im Reflexions-Spiegelungs-Modus gemessen wird, der das Aussehen des Teils misst.

Um die Probe mit ihrer Krümmung genau zu messen, sollte ein kleiner Messbereich verwendet werden. Der kleine Messbereich bietet einen möglichst flachen Bereich auf dem Kunststoffteil für die Messung. Da der Kunststoff leicht ungleichmäßig ist und ein gekrümmter Bereich gemessen wird, ist es am besten, mehrere Messwerte zu mitteln, um eine wiederholbare Messmethode zu erhalten.

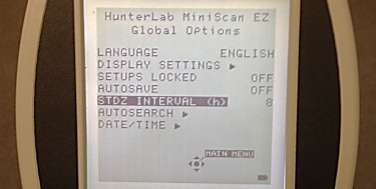

Das MiniScan EZ Kugelinstrument mit kleinem Sichtfeld ist das beste Instrument für die Messungen am Kunststoffteil. Die Kugel ermöglicht die Berücksichtigung des Glanzes und der kleine Sichtbereich hilft dabei, einen möglichst flachen Bereich zu messen. Die Mittelwertbildung mehrerer Messwerte mit dem MiniScan EZ mit kleinem Sichtbereich bietet eine sehr wiederholbare Messmethode für Kunststoffteile wie dieses.