In a fast-paced world, convenience is everything, especially when it comes to food products. With more options than ever before, it’s no wonder that more Americans are choosing shredded cheese over large, solid chunks. With the market for shredded cheeses booming, manufacturers are looking for new ways to extended the shelf-life of these products and reduce waste, and they are turning to spectral analysis for the answer.

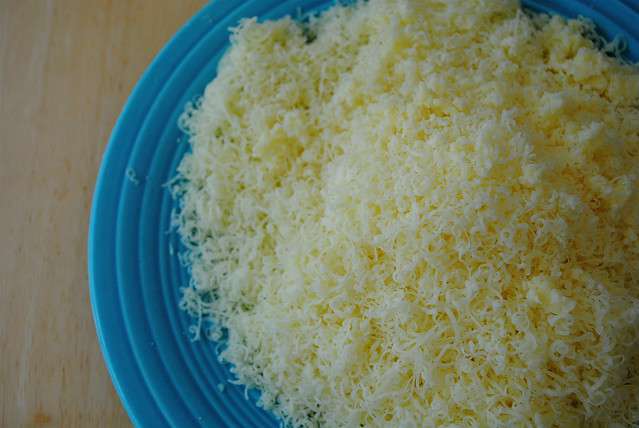

More Americans are turning to pre-packaged shredded cheeses for their quick prep and convenience. Image Source: Flickr user Didriks