Conspicuity is the essential function of High Visibility Safety Apparel (HVSA), protecting workers across the nation who depend on being easily seen to prevent accidents. Highway workers, construction crews, airport personnel, firefighters, and many others rely on the enhanced visibility these garments provide when performing their duties in dangerous areas with low visibility conditions.

HVSA can be important in civilian life as well, for bikers, hunters, or anyone outdoors during hunting season.

While garment manufacturers have a stake in the correct coloration of their products, in the case of HVSA, the obligation has actually been codified into law. According to the U.S. Occupational Safety and Health Administration, workers performing dangerous tasks requiring conspicuity, such as roadside workers, must wear garments that conform to the requirements established in ANSI/ISEA 107-2015. The ANSI standards require that a garment’s material must be tested by an accredited laboratory and certified by the manufacturer with a Declaration of Conformity.

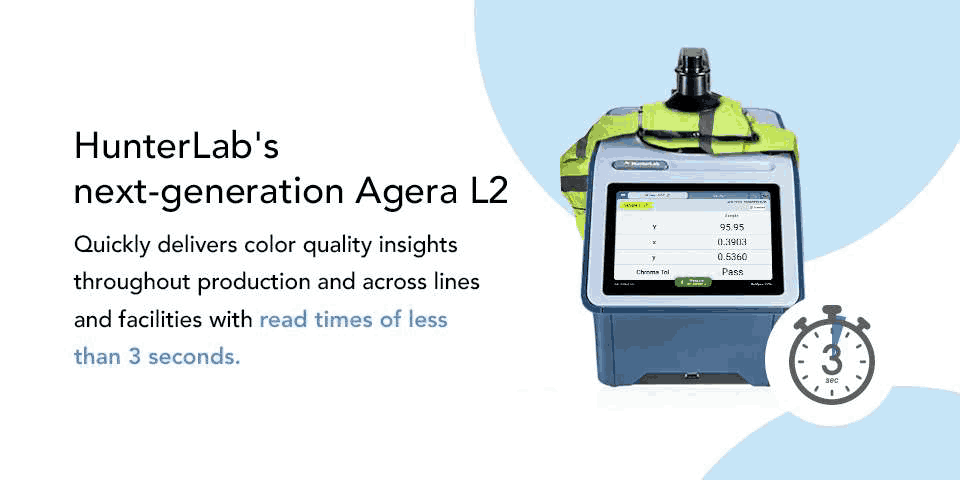

Without proper testing and the ability to guarantee that their HVSA meets ANSI standards, manufacturers face significant risks in sending these products to market. To remain competitive, manufacturers must invest in color quality control equipment and processes, including spectrophotometers/colorimeters.

How Do Spectrophotometers Ensure Compliance With High-Visibility Safety Standards?

Color measurement devices that ascertain the exact color of opaque materials by measuring reflected light are known as reflectance spectrophotometers. HVSA manufacturers depend on these solutions to ensure their clothing meets the color standards prescribed in ANSI 107. The extraordinary degree of color measurement accuracy offered by reflectance spectrophotometers makes them essential to determining the color of these garments and a standard part of safety testing.

ANSI/ISEA standards explicitly require the use of spectrophotometers/colorimeters for both color and colorfastness testing of HVSA. While third-party laboratories perform final certification, manufacturers must incorporate spectrophotometric measurement into their own quality control processes to ensure compliance. These devices prevent costly rejections and delays by confirming garments meet color requirements before they're submitted for certification or shipped to distributors.

Manufacturers can use modern spectrophotometers or colorimeters with dedicated color-measurement software to check how closely production colors align with their specified standards. The software expresses color as numerical values, making it easier to monitor small shade differences and document whether batches fall within defined tolerances.

You can also save standards in the device's memory, so technicians can quickly select the framework they need when testing different batches of clothing.