4. Spectrophotometers Uphold Excellent Quality Control.

Reliable spectrophotometers/colorimeters, like the innovative solutions from HunterLab, offer a scientific approach to measuring the color of resin pellets with accurate and speedy readings. These devices provide quantitative color measurements and valuable data highlighting inconsistencies, allowing you to refine your processes for better quality control.

HunterLab's next-gen Agera L2 is the ideal spectrophotometer/colorimeter for quantifying the appearance of plastic pellets. This advanced solution offers plastics manufacturers precise and objective color measurement for data-based quality decisions. We've engineered the Agera L2 to deliver maximum value in demanding plastic production environments.

Improve accuracy with every measurement. This equipment eliminates unreliable, unscientific visual evaluation methods without compromising the ability to measure color the way humans perceive it. The Agera L2 features 0°/45° circumferential optical geometry and CIE-quality D65 illumination that replicates human vision in daylight conditions for a true representation of appearance.

A built-in, high-definition camera with sample preview helps ensure that users present and position samples correctly to minimize measurement discrepancies. Additionally, role-based user management upholds data integrity, security, and compliance with 21 CFR Part 11.

The Agera L2 drives production efficiency too. An extra-large area of measurement offers 4 to 16 times the sample surface measurement of other spectrophotometers, and results are displayed in under 3 seconds. An automated rotation platform accessory repositions samples at specified degrees and intervals to simplify averaging. This spectrophotometer also features a storage capacity of up to 8GB, or up to 4 million records — perfect for high-volume color analysis.

Plus, the Agera L2 is easy to use, with intuitive navigation and onboard, tablet-based Easymatch Essentials L2 software for independent color workstation functionality. An HDMI port enables monitor connection, while Ethernet and USB ports support fast data exchange and keyboard or mouse additions if preferred. Deploy this equipment at any production stage for fast identification of color alterations to minimize unnecessary waste and empower quick adjustments.

We've also designed the Agera L2 for the unique challenges of color measurement in opaque plastics. Dark Performance Mode provides 6x precision improvements for samples below 20% reflectance, including black, dark gray, and deep blue plastics. Built-in automatic UV calibration simplifies working with samples containing various amounts of brightening agents.

5. Pellet Color Consistency Is Easier With the Right Accessories.

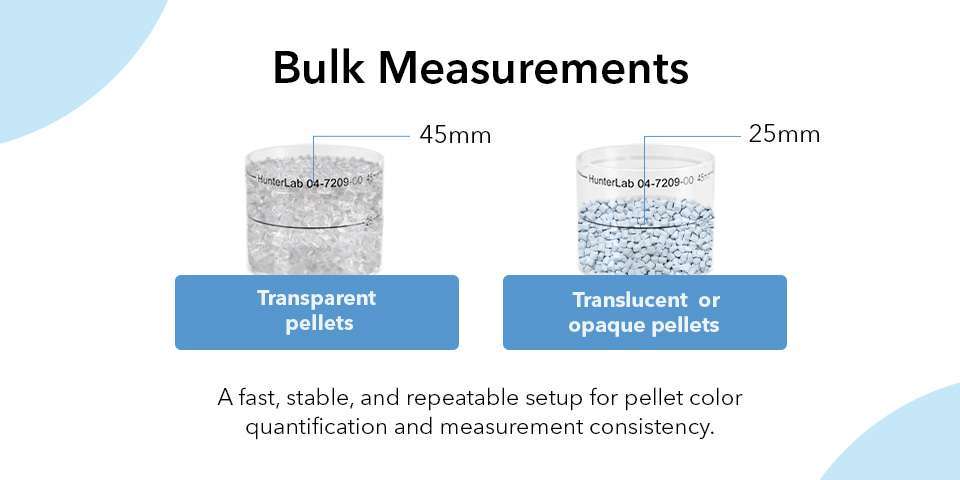

Pellets demand a specialized measurement approach for the highest accuracy and consistent results.

The Agera L2 from HunterLab makes this easy with high-quality accessories engineered for this spectrophotometer and workflow. Our specially designed sample cups, sample cup port plates, and opaque sample cup covers offer versatility across pellets with different opacities.