Understanding Color + Haze Measurement in Gelatin Desserts and Sports Drinks

Customers don’t just see color. They see clarity. And when a previously crystal-clear dessert suddenly looks cloudy, the product risks being perceived as spoiled, stale, or low quality.

That’s why relying on color measurement alone is no longer enough.

With instruments like Vista, you gain real-time, quantifiable insight into both color and haze, helping you:

- Validate appearance during R&D

- Catch issues early in production

- Align teams across R&D, QA, and manufacturing

- Maintain trust in your brand’s visual identity

Want to reduce consumer complaints and rejected batches? Let’s chat about what your customers see first.

Example of Color and Haze Tolerance Ranges for Gelatin Desserts

(Actual tolerances should be determined through product testing, visual correlation, and consumer acceptance studies.)

Color Tolerances (Transmission Measurement)

- ΔE* ≤ 1.0 (typical target for visually critical, brand-defining flavors)

- ΔE* ≤ 1.5 (common production tolerance where minor variation is acceptable)

- ΔE* ≤ 2.0 (upper limit where differences may begin to be noticeable, depending on color and clarity)

Note: In clear products, color differences can appear more noticeable than in opaque foods, especially when haze is low.

Haze Tolerances (Transmission Measurement)

- Haze ≤ 1.0% (Crystal-clear appearance; typical for premium or legacy clear gelatin products)

- Haze ≤ 2.0% (Slight softening of clarity; generally acceptable for products with natural colorants)

- Haze ≤ 3.0% (Noticeable cloudiness; may be acceptable only if aligned with intentional product appearance)

- Haze > 3.0% (High risk of consumer perception issues (cloudy, dusty, or spoiled appearance))

Combined Color + Haze Acceptance Example

A batch may be considered acceptable when both conditions are met:

This prevents situations where a product passes color but fails visually due to excessive haze.

Reformulation Without Guesswork

When switching to natural dyes, even small changes in pH, ingredient sourcing, or processing can cause unexpected haze. Some manufacturers are choosing to reimagine the visual DNA of their products entirely, opting for new, naturally achievable shades instead of trying to replicate synthetic neon colors.

This isn’t a problem. It’s an opportunity.

Using HunterLab’s Vista, manufacturers can measure and compare appearance at every stage of development. That means:

- Testing multiple dye systems before scale-up

- Monitoring pH impacts on clarity

- Confirming each batch meets brand standards

- Tracking shelf-life clarity over time

Let us show you how to reformulate with science, not trial and error.

The Instrument That Sees What Your Customers See

Vista was purpose-built for transparent and translucent food and beverage products. It provides transmission-based measurement, which means it evaluates color and clarity the same way your customers do: how light passes through the product.

In one simple measurement, you get:

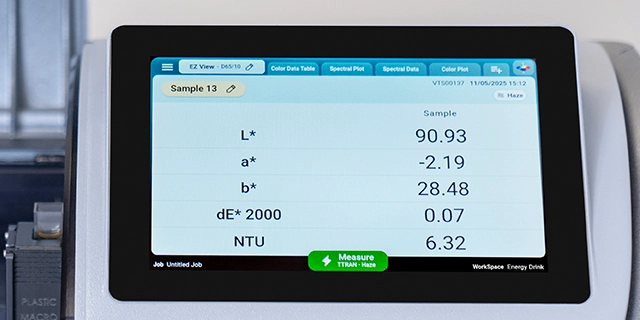

- CIELAB color metrics (L*, a*, b*, ΔE)

- Haze percentage to quantify clarity

- Fast, repeatable results you can trust

Don’t compromise visual quality for label simplicity. With Vista, you can have both.

Clean Label, Clear Product, Confident Brand

The move to natural colorants is not just a compliance issue. It’s a brand opportunity. But only if you can preserve the product experience your customers love.

By combining transmission color measurement and haze measurement, Vista provides a complete, objective view of appearance, helping manufacturers manage reformulation risk, reduce waste, and deliver consistent products. It’s how industry leaders are staying ahead of both regulations and customer expectations.