A leading recycled paper manufacturer faced a costly challenge: inconsistent paper lightness in the cardboard boxes they produced. Since most of their recycled pulp was imported from Europe, variations in color and brightness carried through into the final product. For a company supplying packaging at scale, even minor fluctuations in paper lightness could impact brand quality and customer perception.

The team needed a reliable, non-disruptive way to control pulp lightness before production — and to monitor consistency on the production floor.

Curious how color measurement helps packaging manufacturers achieve consistency and efficiency? Contact Us to see how HunterLab can help.

The Challenge: Variable Color in Recycled Pulp

When paper is recycled, the fibers shorten until they can no longer form strong sheets. To compensate, virgin pulp is blended in — but controlling the exact ratio is difficult. Too little, and the paper looks dark and dull. Too much, and costs rise unnecessarily.

Traditional visual checks couldn’t deliver the accuracy or repeatability this manufacturer required. They needed a fast, objective way to measure pulp color and maintain consistent lightness in their end product.

The HunterLab Solution: Dual-Instrument Precision

HunterLab recommended a two-instrument workflow:

- ColorFlex® L2 – Deployed in the lab to measure pulp solution color. By testing different virgin pulp ratios, the team could fine-tune the mixture before production, ensuring the correct lightness target every time.

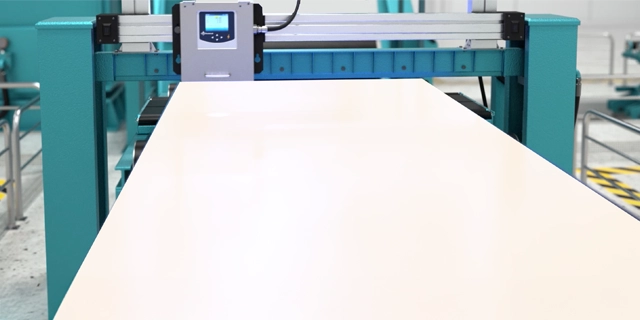

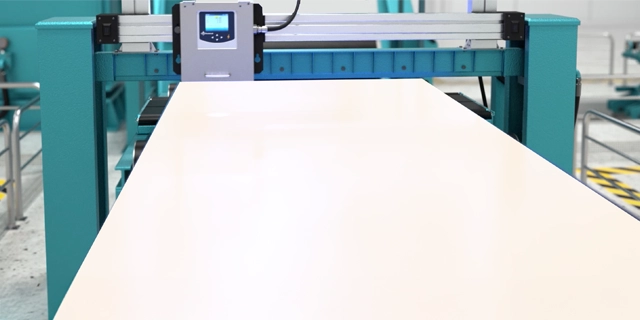

SpectraTrend® HT – Installed in-line to monitor the color of the finished sheets. If drift occurred during manufacturing, operators could immediately adjust the virgin/recycled pulp ratio to restore consistency.

The Results: Improved Control, Lower Costs, and Scalability

With HunterLab’s solution, the manufacturer gained confidence that every batch of recycled paper met lightness specifications — protecting product quality and customer satisfaction.

- Fewer rejects & rework – Consistent pulp color prevented off-shade batches.

- Optimized raw material use – Virgin pulp was added only when needed, reducing waste and controlling costs.

- Scalable process – The company was so satisfied that they planned to purchase a second SpectraTrend HT for a new production line.

INFO Get More Information

Why HunterLab?

For over 70 years, HunterLab has been the trusted leader in color measurement solutions for paper, packaging, and pulp industries. Our instruments combine laboratory precision with production-line efficiency — ensuring manufacturers achieve consistent quality, minimize waste, and meet customer expectations every time.

💡 Ready to achieve color consistency in your recycled paper production?

Contact HunterLab today to learn how our solutions can transform your quality control process.