How a Global Food Manufacturer Went Paperless and Gained Real-Time Color Insight

Kellogg’s, the multinational food giant behind Cheez-It®, made a decisive move to digitize its quality control processes. Their goal: eliminate paper-based documentation and install a real-time color monitoring solution for snack production lines.

To achieve this, they partnered with HunterLab, the trusted name in color science for over 70 years.

🎯 Need to eliminate paperwork and boost precision? Let’s get your plant ready for a digital-first QA workflow. Contact Us

The Challenge: A Need for Real-Time, Reliable Color Data

Cheez-It®'s distinctive golden hue is iconic—but achieving that consistency at scale required more than visual inspection and manual records. Lab-based methods slowed down decision-making and left quality teams reacting to problems after the fact.

Kellogg’s needed an in-line solution to:

- Deliver real-time color data

- Replace paper logs with digital records

- Improve accuracy and operator response time

- Support continuous improvement initiatives

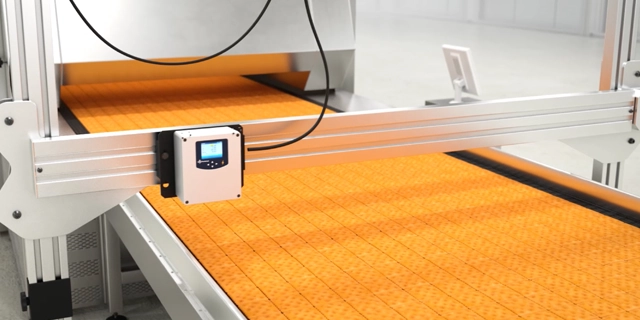

The Solution: SpectraTrend HT In-Process Color Measurement

HunterLab recommended SpectraTrend HT, the premier in-line spectrophotometer built for high-speed food manufacturing. It enables non-contact, continuous color monitoring—delivering instant feedback during production.

Why it works:

- 📏 Measures color in real time using CIE Lab* values

- 💾 Digitally records every reading—no manual logging

- 🔧 Allows operators to make immediate adjustments

- 🧠 Integrates with existing MES and QA systems

The Trial: Turning Data into Confidence

Kellogg’s conducted a weeks-long trial at one of its Cheez-It® facilities, installing SpectraTrend HT to run alongside existing lab tech. The team compared readings in real-time and reviewed logged data across batches.

The outcome? SpectraTrend HT proved its accuracy matched the lab—and delivered results faster, cleaner, and with fewer errors.

Going Paperless with Purpose

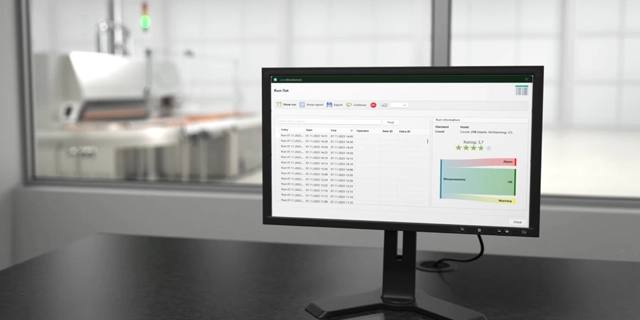

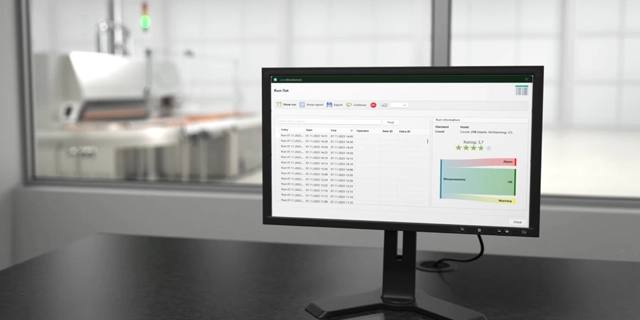

With SpectraTrend HT, Kellogg’s eliminated manual documentation. Operators could now view live dashboards showing color trends, alerts, and statistical process control—all without jotting down a single number on paper.

The shift to digital also brought more visibility across teams and supported Kellogg’s sustainability goals by reducing waste.

The Results: Measurable, Scalable Impact

Post-trial, the results were clear—and impressive:

- ✅ 80% faster detection of color deviations

- ✅ 10% boost in first-pass yield

- ✅ 100% elimination of paper logs

- ✅ Improved sustainability metrics from reduced scrap

The pilot plant commissioned SpectraTrend HT for full production—and plans are underway to expand across Kellogg’s network.

📈 Looking to scale smarter QA across facilities? Start with one line—and grow from there. Contact Us

INFO Get More Information

Why HunterLab?

At HunterLab, we understand the power of color. That’s why the world’s top food, pharmaceutical, and packaging brands trust us to deliver consistent, reliable measurements every time. We don’t just make instruments—we make quality easier, faster, and more precise.

From lab to line, HunterLab delivers end-to-end color solutions backed by science and service.

Get Started Today

📞 Talk to a Color Expert

We’ll walk your team through setup, training, and ROI planning.

📽️ Watch a Demo

See SpectraTrend HT in action on the food line.

🧪 Request a Trial

Test real-time precision with your product on your floor.

🚀 Ready to take the next step like Kellogg’s? Future-proof your quality program. Contact Us