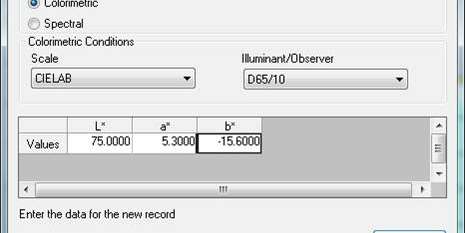

Enter Standard Data window

FAQ: “Do you have a formula to calculate Hunter L, a, b values from CIE L*, a*, b* values?”

The only way to convert between different color scales, illuminants, and observers is to have spectral data for your samples.

All Hunter L, a, b and CIE L*, a*, b* values are calculated from X, Y, Z values and chromaticity coefficients for the illuminant and observer used. Most color scales are calculated using CIE X, Y, Z tristimulus values. Spectral values from the sample measurement allow for conversion between different color scales, illuminants, and observers because X, Y, Z CIE tristimulus values are calculated from spectral values.

That being said, the HunterLab EasyMatch QC software does have the ability to convert color values assuming you are using the same illuminant and observer. To do this you will first need to enter the color values you want to convert into the EasyMatch QC software. This is done by right clicking in the Job Tree and selecting Enter Standard (or Sample) Data. Select the appropriate color Scale and Illuminant/Observer combination, enter your data, and click OK. Once you enter the Standard (or Sample) ID the values will appear in the Color Data Table.

To convert these values move the mouse to the Color Data Table, right click, and select Configure. Use the drop down menu under Scales to select the color scale you would like to convert to and use the left arrows to move it to the Selected Items list. Click OK to save your changes.

In the Color Data Table you should now see your converted color values.