Protecting Brand Integrity Through Color Precision

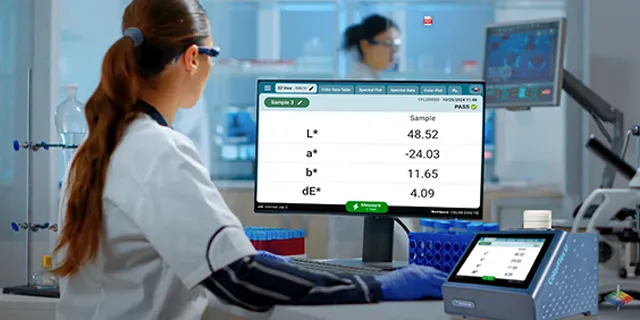

Inconsistent ingredient color can cost manufacturers millions in rejected batches, regulatory setbacks, and lost consumer trust. For global ingredient leader Kemin Industries, ensuring color accuracy is not just an aesthetic concern—it's central to product quality and customer satisfaction. That’s why Kemin relies on HunterLab's advanced color spectrophotometers to protect the integrity of over 500 ingredient solutions across food, pet nutrition, and more.

Operating across more than 20 countries with 15 production facilities, Kemin faces the complex task of maintaining visual uniformity in highly diverse ingredient forms. From powders and granules to liquids and pellets, their customers expect one thing: consistency. And in today's competitive baking and snack markets, even slight color deviations can signal oxidation, processing errors, or shelf-life risks.

The Challenge: Detecting Oxidative Change Before It Affects Quality

Lipid-based oxidation is a persistent challenge in the baking and snack industries. As fats and oils degrade, they visibly darken ingredient color—even before other sensory qualities change. These early shifts can result in customer dissatisfaction or failed quality checks.

For Kemin, early detection of these subtle changes is essential to delivering on their promise of quality. They needed a solution that was:

- Sensitive enough to catch imperceptible color shifts

- Scalable across facilities and ingredient types

- Easy to operate with minimal variability between users