Top-Rated Color Measurement Solutions for Quality Assurance include devices like spectrophotometers that use optical geometries (such as 45°/0° and d/8°) to ensure precise, reproducible color measurements across batches and locations. The best solutions will:

- Measure both reflectance and transmittance color accurately.

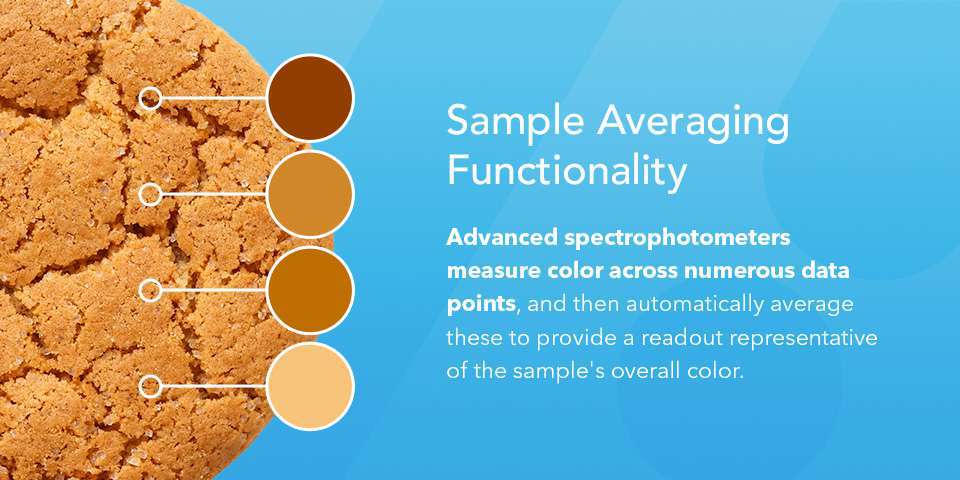

- Support sample averaging for uneven textures.

- Integrate seamlessly with QA software.

- Come from trusted manufacturers like HunterLab.

Looking for the top-rated color measurement solutions for quality assurance? Whether you're in food production, pharmaceuticals, plastics, or textiles, accurate color measurement is critical to maintaining quality, consistency, and compliance. In this guide, we’ll break down what makes a solution “top-rated” and how to select the best spectrophotometer based on your sample types, workflows, and regulatory needs.

As a manufacturer, you know best how fierce the market you operate in can be. Every advantage that sets your products apart on crowded shelves is one worth creating and maintaining, making quality nonnegotiable as a competitive advantage. Accurately determining product color is instrumental in upholding quality, which is where top-rated color measurement solutions deliver tangible value.

Maximize your investment by understanding the connection between color measurement and quality assurance (QA) and exploring tips for choosing the best color measurement solutions.

Why Top-Rated Color Measurement Devices Are Essential for Quality Control

Color measurement and quality assurance are inarguably entwined. Achieving and maintaining a consistent appearance across products, batches, and facilities helps your organization:

- Meet consumer expectations: Visual interactions are among the first experiences customers have with your products, and they're a key driver in their purchasing decisions. If goods don't meet their appearance expectations, consumers will quickly form a negative impression of your brand and reach for a competing product instead.

- Reduce waste: Manufacturing certain products requires tight color tolerances. For example, color can indicate the efficacy of active pharmaceutical ingredients. Medications that don't meet color specs could be unsafe and must be discarded. Consistent measuring of color at each step helps prevent waste and resulting financial loss.

- Achieve brand recognition: Consumers often associate specific colors with the brands they're loyal to. Ensuring these colors are consistent upholds integrity and strengthens recognition.

- Comply with regulations: If your operations fall under the oversight of governmental agencies like the Food and Drug Administration (FDA), color measurement is critical to preventing costly noncompliance fines and penalties.

Traditionally, streamlining QA workflows for color and quality measurement to achieve these goals was challenging. Visual color inspections and comparisons are unreliable and inherently subjective. Evaluator fatigue and differences in the observational environment often produce errors.

Top-rated color measurement solutions, like spectrophotometers, are the smartest approach to measuring color quality. These devices accurately determine color by quantifying the intensity of light at various wavelengths, transforming reflected or transmitted light into objective numerical values. Integrating a top-rated spectrophotometer from a respected manufacturer like HunterLab helps you elevate color control processes, ensure product visual integrity, and support your products' overall success.

Use the following criteria to evaluate top-rated color measurement solutions for your QA workflows.

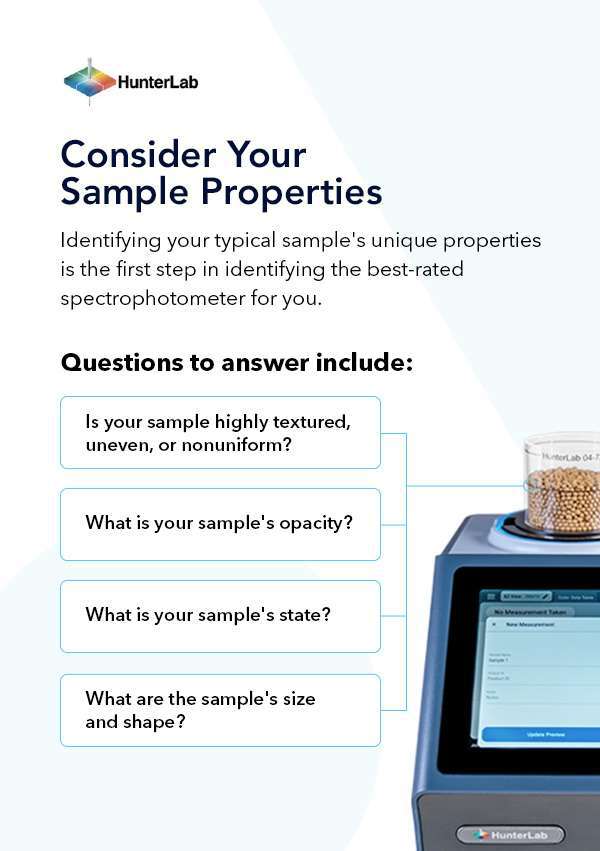

1. Consider Your Sample Properties

Identifying your typical sample's unique properties is the first step in identifying the best-rated spectrophotometer for you. These traits determine the necessary optical configuration, geometry, features, and accessories for the task.

Questions to answer include:

- Is your sample highly textured, uneven, or nonuniform? These products create unique challenges for color quality control and require solutions designed for the inherent variations.

- What is your sample's opacity? Transparent samples require one measurement approach, while fully opaque samples require another. The best measurement method for translucent samples differs based on how much light can pass through them.

- What is your sample's state? Solids and liquids need different measurement techniques and accessories. For example, loose powders may need special sample holders or port plates for accuracy, while liquids require cuvettes and may need flow cells.

- What are the sample's size and shape? Samples in some industries, such as pharmaceuticals, are costly. Small-volume containers and a spectrophotometer capable of accurate readouts on minimal sample sizes are essential for cost containment.