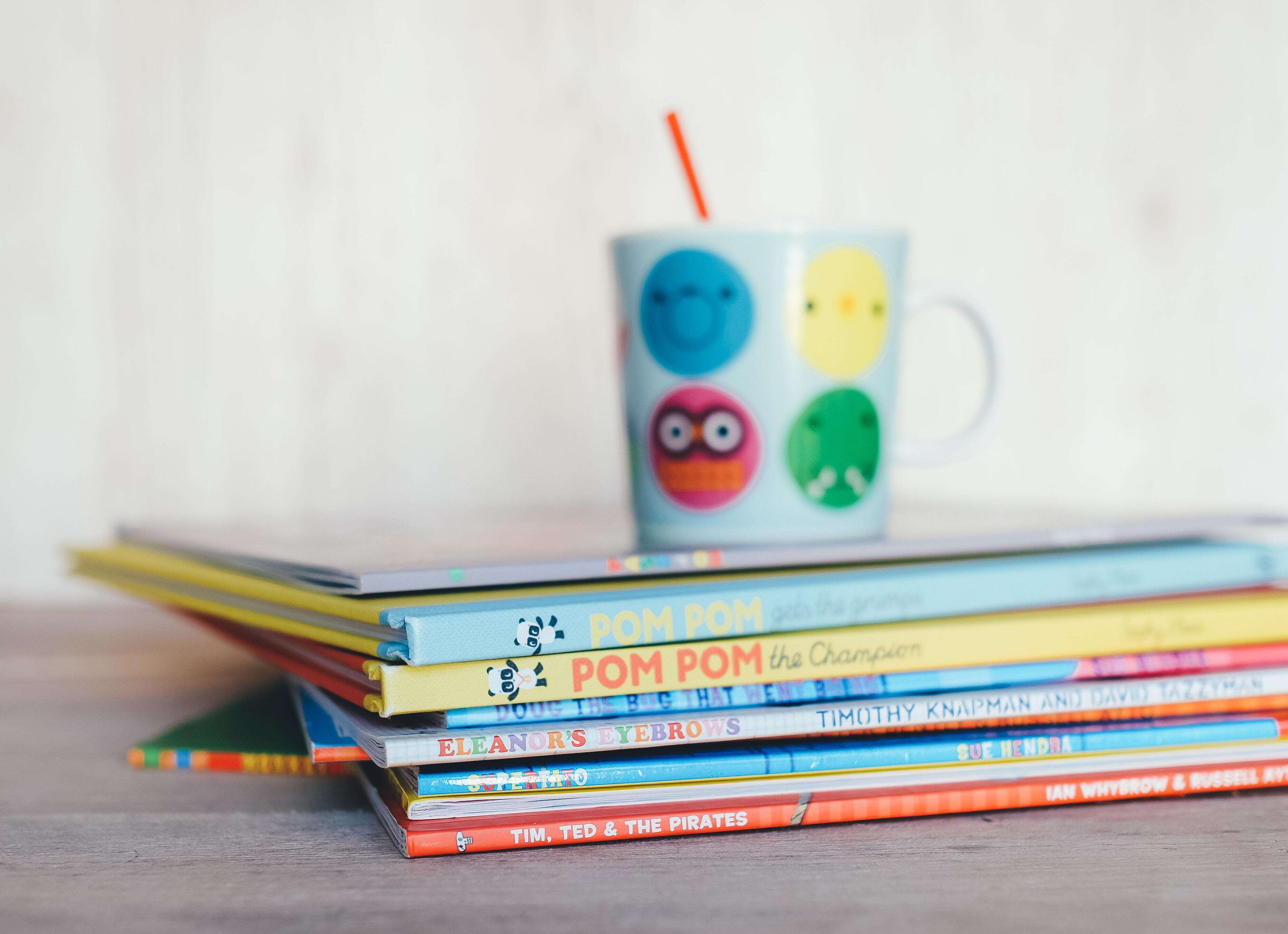

Despite the emergence of digital technologies, printed media still plays a vital role and gives us opportunities for visual communication unmatched by digital alternatives. Image Source: Unsplash user Annie Spratt

In an age of digital media, it can sometimes be easy to forget the simple pleasure of sitting down with a magazine, book, catalog, or newspaper. There is something special about having an object in your hands, feeling the paper, and seeing images exactly the way they were meant to be viewed. After all, paper and ink ensure that every viewer sees the same photographs and illustrations without the slight color variations inherent to screens, making them irreplaceable when image quality is a top priority. Whether it’s giving customers an exact representation of a product color, creating an artist catalog, or showcasing the carefully chosen colors of a designer’s latest collection, there is nothing quite like printed media.

Of course, the quality of printed media depends on the quality of the ingredients, particularly ink. As The Stothard Group says, “The very simple reality of producing ink is that the customer is buying color.”1 Those colors must be both accurate and consistent, allowing for print media customers to create exact reproductions of photographs and illustrations again and again throughout the run of a particular product as well as in potential future reprints. While it is easy to recognize the importance of ink color quality when producing media such as artist catalogs or coffee table books, even mass-produced, everyday items like magazines depend on color consistency for marketability.

[Magazines] are normally going to be laid out next to each other on shelving in a shop. If the ink is even a slightly different color, whether a different hue or too light or two dark, it will be instantly noticeable and reduces the perceived quality of the product being sold. If the colors dull from magazine to magazine, they will not be as vibrant on the shelves and therefore not as appealing to a customer.

Indeed, despite the move toward digital media, printers are “under more pressure to produce highly accurate color” than ever before.2 “Commercially acceptable color has been redefined over the last decade,” says Steve Miller, color systems technology manager for Kohl and Madden, the commercial inks division of Sun Chemical. “Printers are being pushed hard by brand owners to match colors precisely. This has given rise to the use of spectrophotometers and color-matching software, which provide tighter tolerance on measurements.”

Spectrophotometric measurement of ink color ensures accurate, consistent printing that enhances the quality and appeal of printed media. Image Source: Pexels user Noe Araujo