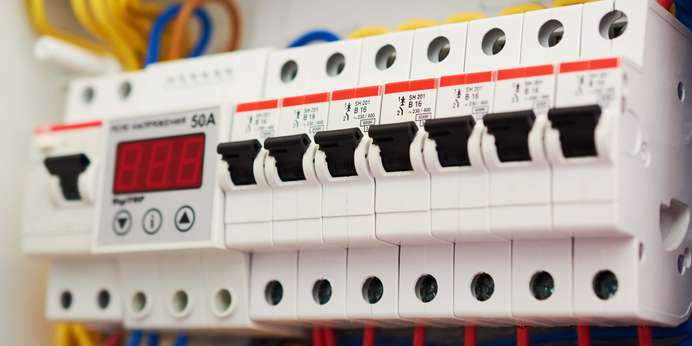

Opaque plastic enclosures are boxes that hold and protect electronic equipment from harsh environments. They typically include circuit breakers, contactors, control panels, switches, and more.

Companies rely on color consistency and solidity of these enclosures for ultimate protection. Here are some best practices when measuring the color of opaque plastic enclosures.

Choose the Right Tool

The first step needed is to choose the right solution for your product measurements. Many product plants use spectrophotometers — machines that provide numerical data to measure color quality and consistency.

HunterLab offers several elite spectrophotometers for the job. Specifically, opaque plastic enclosures can be best measured using the Agera. This tool can thoroughly analyze 3D structures for accurate and precise color data.