Las especias aportan sabor culinario y atractivo visual, y su color influye significativamente en la percepción del sabor, la calidad y la frescura. Las alteraciones en el aspecto pueden identificar procesos que requieren cambios para mantener la calidad del color. La medición precisa del color de las especias proporciona datos cuantificables para confirmar si estas cumplen con las tolerancias aceptadas por la industria, los estándares de calidad y las expectativas de los clientes.

El valor del análisis preciso del color de las especias

Hay varias razones de peso para medir el color de las especias:

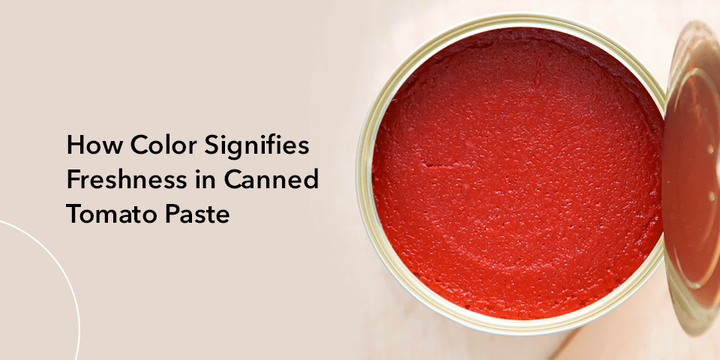

- Control de calidad: Los consumidores juzgan la calidad de los alimentos por su color, y el alto contenido de humedad, las fluctuaciones de temperatura durante el almacenamiento y la antigüedad de las especias influyen significativamente en su aspecto. La cuantificación y el control de la calidad del color de las especias contribuyen a obtener productos finales de mayor calidad.

- Impacto comercial: Las personas también esperan que ciertos colores de las especias realcen el atractivo visual de los alimentos. Ofrecer siempre el color deseado fomenta la lealtad a la marca y puede crear entusiastas de la marca para toda la vida.

- Conformidad con las normas: Algunas especias, como el pimentón y las especias oleorresinosas, deben cumplir normas industriales específicas. Otras especias utilizan diferentes espacios de color reconocidos por la industria, como Hunter L, a, b. Las mediciones precisas documentan la conformidad con los marcos normativos.

Integración de mediciones en todo el proceso de fabricación

La realización de múltiples mediciones permite a los fabricantes supervisar la calidad del color en puntos críticos de la producción, lo que simplifica la identificación de problemas y facilita su resolución temprana para reducir los residuos. La cuantificación de los datos en diversas etapas también permite determinar con precisión dónde se producen las alteraciones del color, lo que permite realizar ajustes de forma proactiva. Considere la posibilidad de implementar la medición del color en toda la producción, desde las inspecciones de las materias primas hasta la captura de datos de color durante el proceso y la verificación del producto acabado.

Consideraciones de muestra para fabricantes de especias

Las especias plantean retos únicos en cuanto a la medición del color, entre los que se incluyen:

Tamaño de la muestra frente a coste

El tamaño de la muestra puede no ser relevante para quienes trabajan con especias de bajo coste, como la pimienta negra, pero cuantificar el color en especias de alto coste, como el azafrán, supone un gasto más significativo. Los fabricantes de estas especias más costosas se benefician de minimizar la cantidad de muestra necesaria. Una solución de medición del color altamente precisa y exacta aporta una mayor confianza en los resultados, incluso con muestras más pequeñas. La herramienta adecuada también significa menos desperdicio de ingredientes valiosos, por lo que se destina más a las estanterías de las tiendas y a sus resultados finales.

Materiales no uniformes

Las especias son naturalmente heterogéneas, ya que contienen diversas texturas, tamaños y formas procedentes de las partes procesadas de las plantas. Las mezclas como la sal sazonadora o el curry en polvo aumentan aún más la complejidad al combinar diferentes ingredientes especiados. Estas variaciones hacen que las comparaciones visuales sean poco fiables y que la captura de datos precisos resulte difícil sin la tecnología adecuada.