Every material absorbs, reflects, or transmits light, which determines the color we see when looking at an object. Transmission refers to the light waves that pass through a translucent or transparent sample, and spectrophotometers provide quantitative measurements of that data. These devices make it possible to evaluate a sample's color scientifically and objectively, which is vital for ensuring color consistency in various applications. Spectrophotometer transmittance measurements enable better quality control and enhanced consumer perception of your products.

What Is Transmittance in a Spectrophotometer?

The definition of transmittance is the measured light that passes through a sample, meaning the light that is not absorbed or reflected. Three primary transmittance measurements include:

- Diffuse transmittance (Td, n): This measurement is the ratio of the flux transmitted by a specimen to the incident flux, with the transmitted flux being measured at all forward angles except the regular transmission angle. When light is diffusely transmitted, its direction changes as it passes through the material, causing scattering.

- Regular transmittance (tr, n): This measurement is the ratio of undiffused transmitted flux to incident flux. In other words, it is straight-through light.

- Total transmittance (tt, n): This measurement is the ratio of the flux transmitted at all forward angles to the incident flux. Total transmittance is the sum of regular transmittance and diffuse transmission.

These values are essential to maintaining quality in products like beverages and edible oils. It's best to measure color with a spectrophotometer to capture more accurate information, as these devices provide exact quantitative data regarding the amount of light that passes through a sample.

The transmittance formula is:

T = PT/P0

The values in this formula represent:

- T: Transmittance

- PT: The source's radiation power as it exits the sample

- P0: The source's radiation power as it enters the sample

The resulting calculation is a ratio, comparing the light before it enters the sample to the light after it passes through it. A value closer to 1 means most light passes through, while lower values mean that less light passes through.

What Is Percent Transmittance in a Spectrophotometer?

Percent transmittance displays the light that passes through the sample as a percentage rather than the ratio created by the above formula. You can get the value by multiplying the ratio by 100.

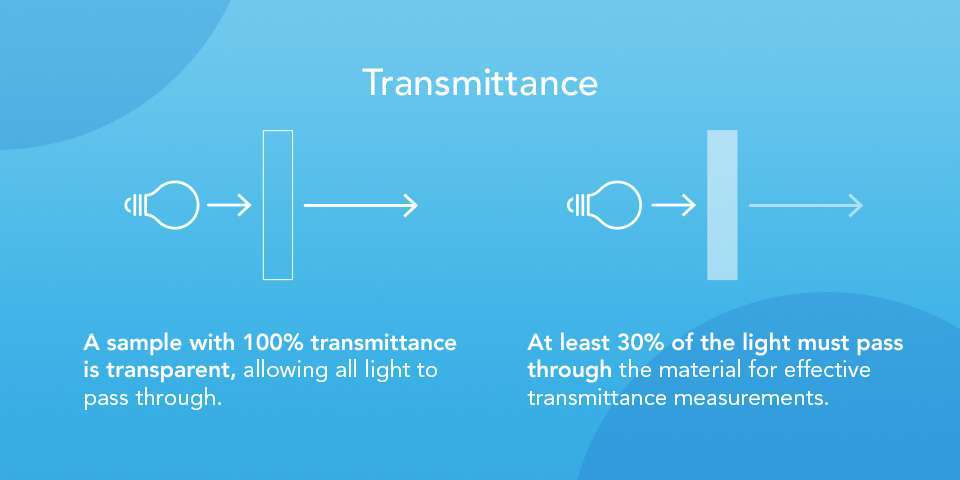

A sample with 100% transmittance is transparent, allowing all light to pass through. Lower numbers indicate more translucence than transparency. At least 30% of the light must pass through the material for effective transmittance measurements.

The transmission percentage is also helpful for absorbance calculations. A commonly used absorbance formula is:

A = 2-log10(%T)

This formula determines the amount of light absorbed using the percentage of light that passes through the sample.