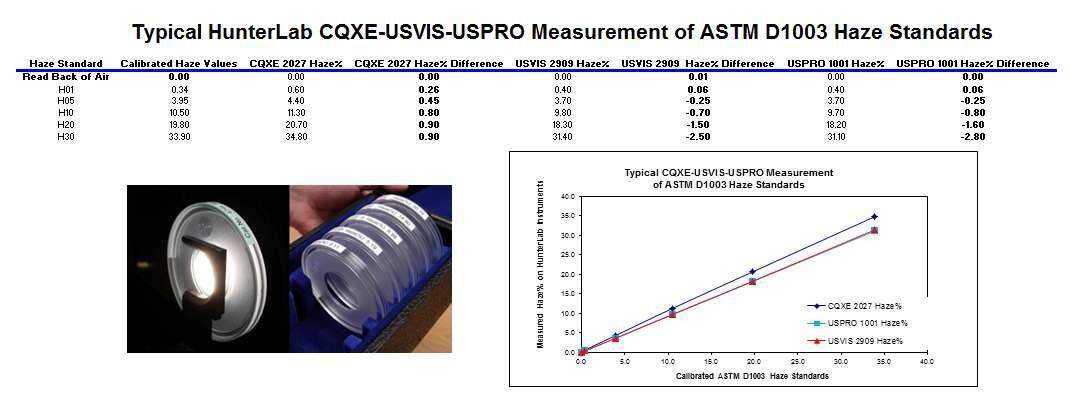

HunterLab sphere instruments with CIE d/8 geometries conform to the requirements of ASTM D1003 Section 8: Procedure B Spectrophotometer. The measurement of transmission haze using Procedure B instruments will be in close agreement with ASTM D1003 Procedure A Haze meter.

Meeting ASTM D1003 Section 8 Procedure B Requirements

Here is a more detailed description of how the HunterLab UltraScan PRO and UltraScan VIS meet the requirements of Section 8.

- Procedure B (Spectrophotometer)

8.1 Apparatus:

8.1.1 The instruments used for measurement shall meet the geometric and spectral requirement of this section.

HunterLab UltraScan VIS and UltraScan PRO instruments meet ASTM D1003 Section 8 Procedure B Spectrophotometer requirements.

8.1.2 The instrument shall be capable of computing from the spectral data the 1931 CIE tristimulus values and related color coordinates for CIE standard Illuminant C or alternatively Illuminant A.

HunterLab offers A/2 and C/2 options for calculating Haze%, Y Total and Y Diffuse luminous transmission in EasyMatch QC software.

8.1.3 The instrument shall utilize a hemispherical optical measuring system, with an integrating sphere, in which the specimen can be placed flush against the sphere port. The surfaces of the interior of the integrating sphere, baffles, and reflectance standards shall be matte, of substantially equal reflectance and highly reflecting throughout the visible wavelengths.

HunterLab UltraScan VIS and UltraScan PRO sensors and internal components are coated with Spectralon having a 99%+ reflectance. Transparent specimens for haze measurement are placed at the TTRAN port, flush against the sphere.

The UltraScan VIS and Pro come with white, Japanese commercial opal reflectance standard of 99%+ reflectance.

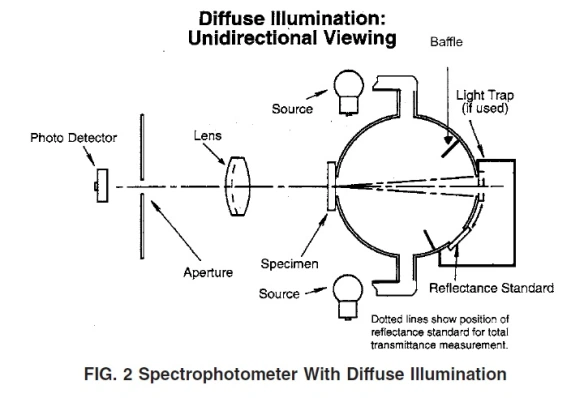

8.1.4 Two geometries can be used: unidirectional illumination with diffuse viewing and diffuse illumination with unidirectional viewing. Using diffuse illumination with unidirectional viewing, the following apply:

HunterLab UltraScan VIS and UltraScan PRO sensors have a diffuse illumination with unidirectional viewing (8°) geometry. They are referred to as CIE-conforming diffuse d/8° sphere instruments.

8.1.4.1 Use an integrating sphere to illuminate the specimen diffusely; the sphere may be of any diameter as long as the total port areas do not exceed 4.0 % of the internal reflecting area of the sphere. The specimen and light trap ports of the sphere shall be centered on the same great circle of the sphere, and there shall be at least 2.97 rad (170°) of arc between their centers.

The light trap port shall subtend an angle of 0.14 rad (8°) at the center of the specimen port along the wowing beam. With the light trap in position, without specimen the axis of the viewing beam shall pass through the centers of the specimen and light trap ports.