Hidden in the byzantine halls of the U.S. Secret Service lies a nondescript library. In this seldom-visited area are contained the exact profiles of more than 11,400 writing inks. Using the latest high-tech devices, agents can pinpoint the origins of any writing ink. Each contains, within its complex chemical makeup, clues as to origin—clues that can be traced back to the manufacturer, year produced, and even batch.

Only select investigators might wholly understand this analysis process. But the fact that inks are so sensitive, so infinitely varied, should come as no surprise to anyone who manufactures them.

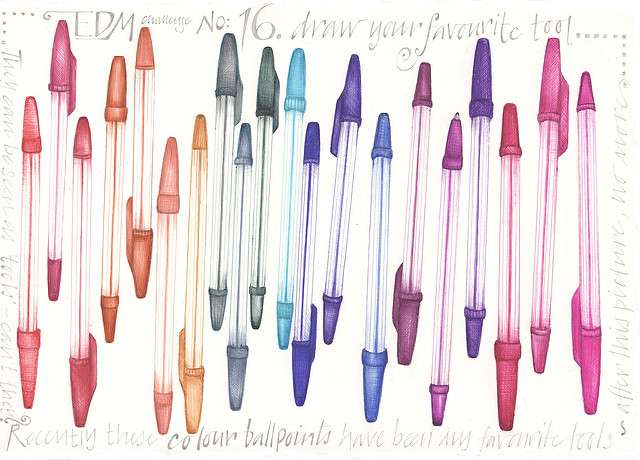

Who’s Got the Ballpoint Pen Blues?

Different manufacturers produce different materials; different materials make different inks. As Lisa Hahn, President of Flexo Tech, puts it, “Blue is not blue is not blue. I may have a blue that’s somewhat chlorinated so that it has a green shade. But a blue from Company A may not have the same shade of green tint as the one from Company B. While they may have the same degree of blueness the undertone will not be the same.”1

Thus, when managing the production of inks for ballpoint pens, it’s essential to implement an effective color quality control system to identify even slight variations from the standards that have been prescribed by clients or a parent company.