The true key to business longevity lies in your products. What you offer has to work as expected — more than that, it has to be safe, functional, and fit any standards you and other governing bodies have set forth. Ensuring that requires testing and more testing, and that's what performance qualification is all about.

What Is Performance Qualification?

The United States Food and Drug Administration (FDA) defines performance qualification (PQ) as establishing confidence in your finished product or process by testing it before release. This testing should determine whether:

- The product meets functionality and safety requirements.

- Any results can be easily reproduced.

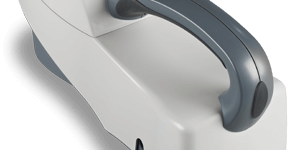

For example, HunterLab's MiniScan EZ 4500 portable spectrometer can identify color using some of the most common color scales and indices. We promise this capability in the product's description. Before we could release that information, we had to complete performance qualification.

To do so, we tested hundreds of color samples to ensure that our spectrometer got the answer right every time. When it didn't, we adjusted our product and tested it again and again until it was as accurate as possible. By the time the product hit the market, we were sure it was ready for wide release.