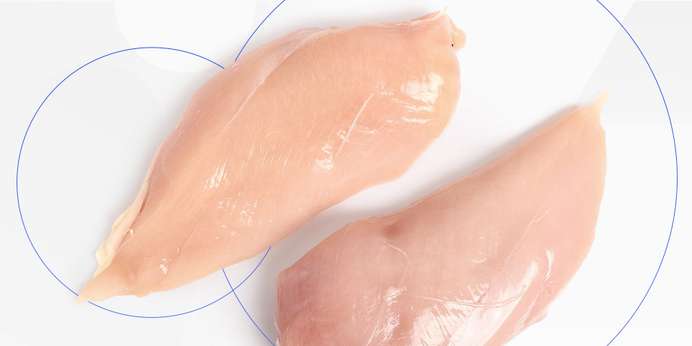

What Color Is Poultry?

What exactly gives poultry that pale pink color it's known for? Like other meats, reddish and pink hues come from oxygen interacting with the meat's myoglobin, a natural compound that stimulates muscles. This same feature creates distinctions between white meat and dark meat — there is a higher concentration of myoglobin in poultry legs and thighs since these constitute the muscles birds use most often.

During cooking, poultry will occasionally darken or keep part of its pinkish hue. Both of these reactions are normal and will not affect flavor or healthiness, so long as the meat is cooked to at least 165°F. Changes in coloration to look out for include dullish hues, especially if they have gray or green undertones, and sliminess that does not go away with rinsing.

Why Does Poultry Color Need Measuring?

While most people know with a glance whether a package of poultry is good to buy, color has played an important role in this knowledge and continues to do so. If the poultry color looks off to someone, they likely won't buy it, instead moving to a competitor brand that caters more to their expectations. However, since color is subjective based on the person perceiving it, using color measurement tools like spectrophotometers has become common practice for many food manufacturers.